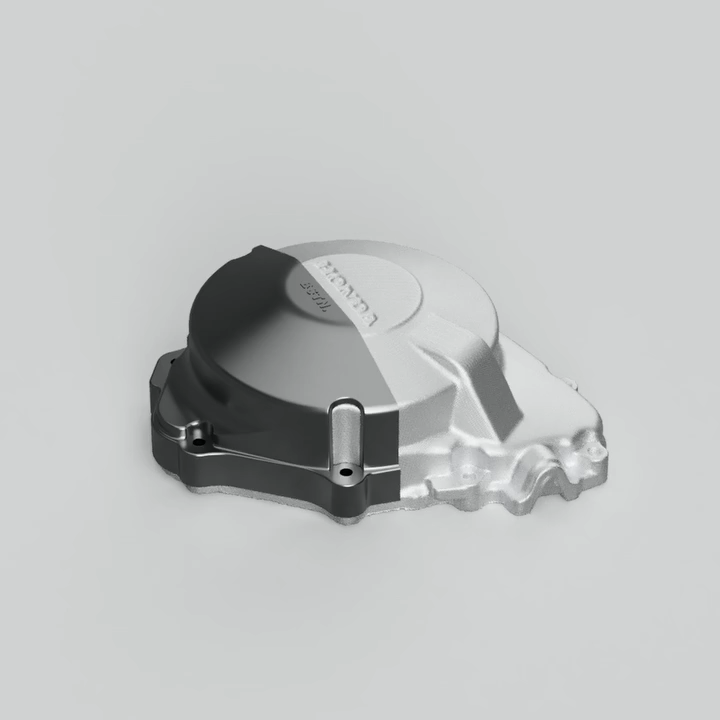

Engine Covers — CBR600 F2/F3

Custom engine covers designed and produced for pre-modern racing where OEM replacements are hard to source. Built from 3D scans, iterated through test prints, then produced in PA-CF for heat and abrasion resistance.

Overview

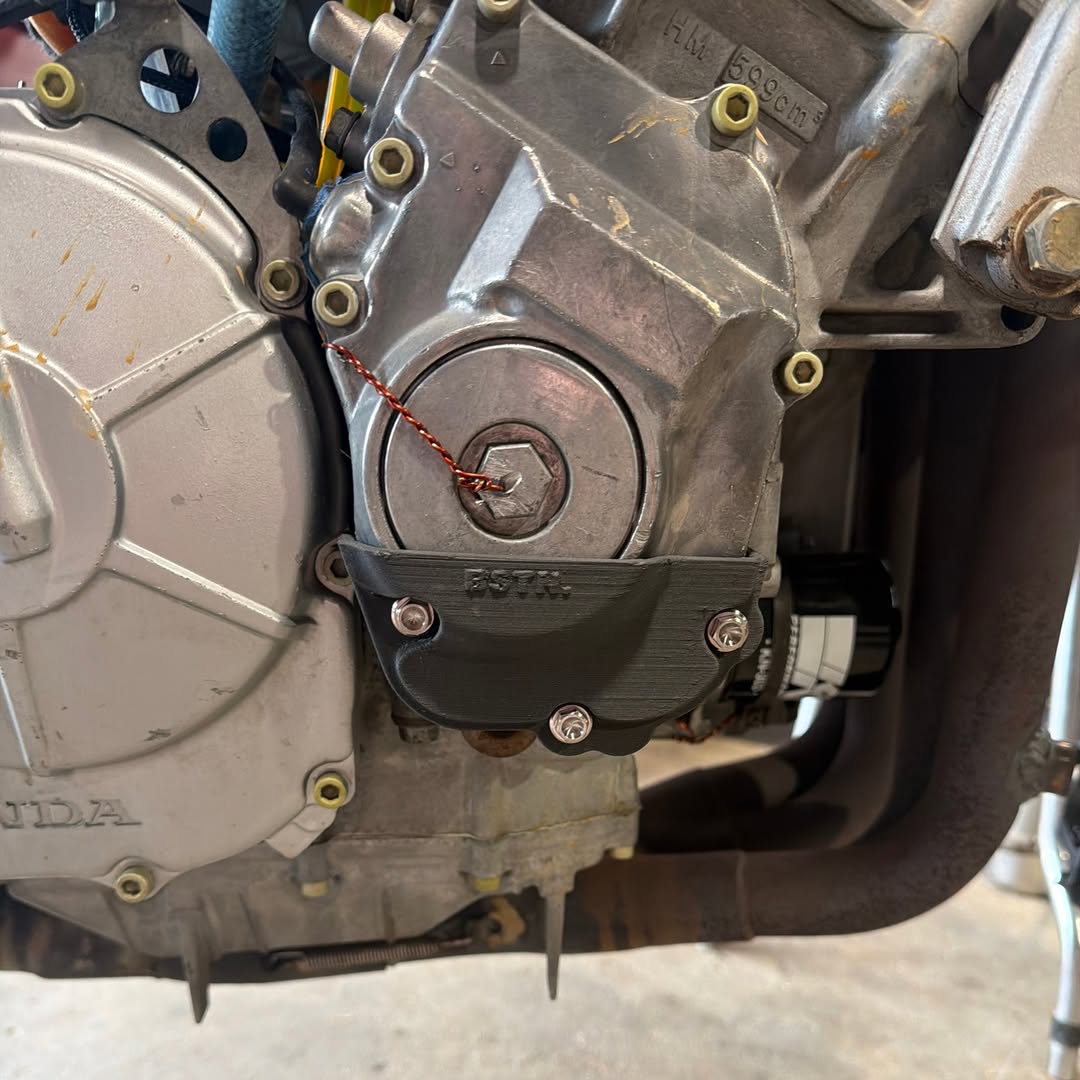

Replacement covers for older bikes like the CBR600 F2/F3 are difficult to find, so these were created as a functional alternative for a rider competing in pre-modern racing. Original engine cases were scanned to capture geometry accurately, then imported into Fusion 360 for modelling and refinement. Multiple fitment iterations and test prints were used to reach the final design. The finished parts are printed in carbon fibre–infused nylon (PA-CF) for strength, heat resistance, and low-friction abrasion performance near the engine.

Key Features

3D scan–based modelling for accurate geometry capture

Iterative fitment process with test prints

Functional replacement solution for hard-to-source OEM parts

PA-CF chosen for heat resistance and durability

Low-friction, abrasion-resistant surface behaviour for racing use

Specifications

- Material

- Carbon Fibre–infused Nylon (PA-CF)

- Print Method

- FDM

- Weight

- Dimensions

- Post-Processing

Design Process

3D scan original engine cases for reference geometry

Import scan data into Fusion 360

Model cover geometry and mounting interfaces

Run fitment test prints and iterate for clearance

Finalize design for strength and abrasion behaviour

Print final parts in PA-CF and validate fit

Gallery