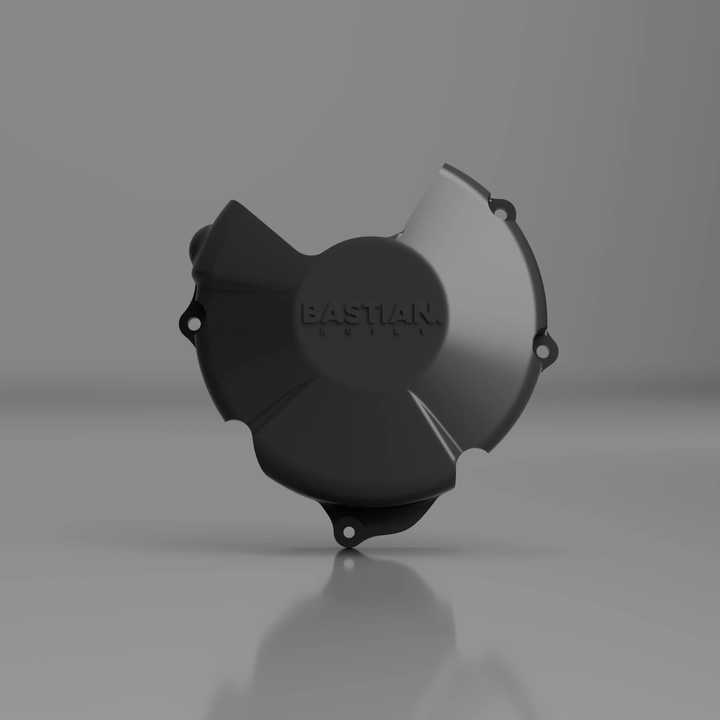

CBR600RR Engine Case Cover

Engine case covers designed from a 3D scan of the OEM case to lock in clearances and fitment. Modelled using surface techniques to speed up complex geometry creation, then printed as a solid, sacrificial protection part for high-impact areas.

Overview

Designed directly over a 3D scan of the OEM engine case, these covers were built to achieve reliable clearances and a true “bolt-on” fit before fabrication. Surface modelling was used instead of traditional solid modelling to form the complex curvature quickly, cutting modelling time significantly. The final covers are printed with a thick 4mm wall and solid infill in carbon fibre–reinforced nylon for heat resistance, low friction sliding, and abrasion resistance in impact zones.

Key Features

3D scan–referenced geometry for accurate clearances and fitment

Surface-modelled form for fast creation of complex curves

4mm wall thickness for robust sacrificial protection

Solid infill construction for maximum impact durability

CF-reinforced nylon for heat resistance, low friction, and abrasion performance

Specifications

- Material

- Carbon Fibre–reinforced Nylon (PA-CF)

- Print Method

- FDM (solid infill, 4mm wall)

- Weight

- Dimensions

- Post-Processing

Design Process

3D scan OEM engine case as dimensional reference

Import scan into Fusion 360 and establish fitment clearances

Surface modelling to generate complex cover geometry efficiently

Iterate model and validate clearances

Print in PA-CF with thick wall and solid infill

Final fitment check and refinement as needed

Gallery