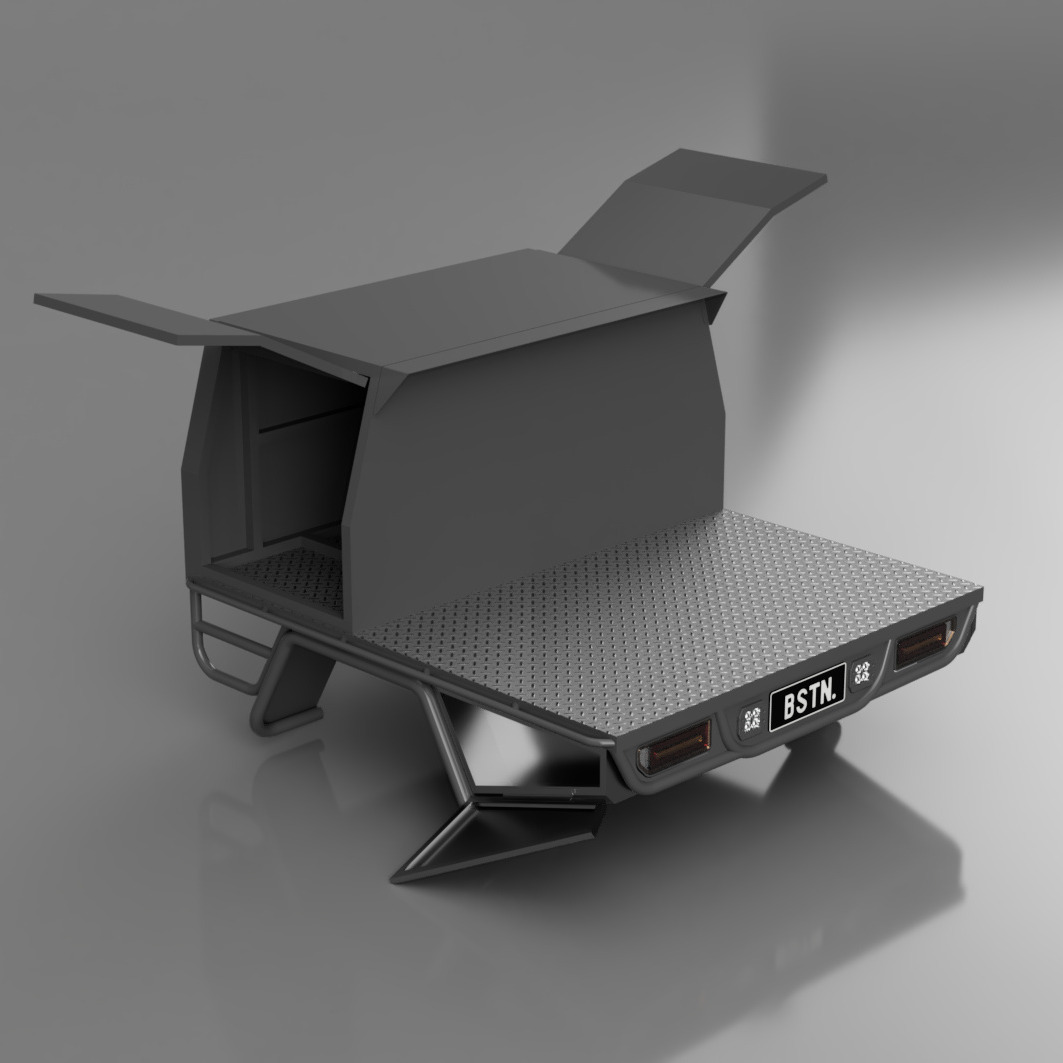

1780 × 2000 mm Tray — LN106 Single Cab (Beta Design)

Early-stage CAD tray concept for a single-cab LN106, designed around APB canopy and under-tray boxes with integrated lighting mounts and animated components for motion testing.

Overview

A beta-stage custom tray design sized at 1780 × 2000mm for a single-cab LN106. The layout accommodates an APB canopy and under-tray storage, with clean integrated mounts for JB74 tail lights and recessed Stedi C4 reverse/flood lights. The CAD includes animated components (like opening doors) and modular mounting points to validate motion, clearances, and accessory placement. Future refinement is planned, including 3D scanning the rear cab and chassis to digitally capture mounting points and confirm fitment in a full vehicle assembly.

Key Features

1780 × 2000mm footprint tailored to LN106 single cab

Designed to suit APB canopy and under-tray boxes

Integrated mounts for JB74 tail lights

Recessed rear Stedi C4 reverse/flood light integration

Animated CAD components for motion/clearance validation

Specifications

- Material

- Print Method

- N/A (CAD for fabrication)

- Weight

- Dimensions

- 1780 × 2000mm

- Post-Processing

Design Process

Define tray requirements (canopy, boxes, lighting, mounts)

Build primary tray geometry and packaging in CAD

Integrate lighting mounts and recessed housings

Add modular accessory mounting interfaces

Animate key components for motion and clearance checks

Plan next phase: 3D scan cab/chassis for exact mounting integration

Gallery